Product Information

Permanent Signage

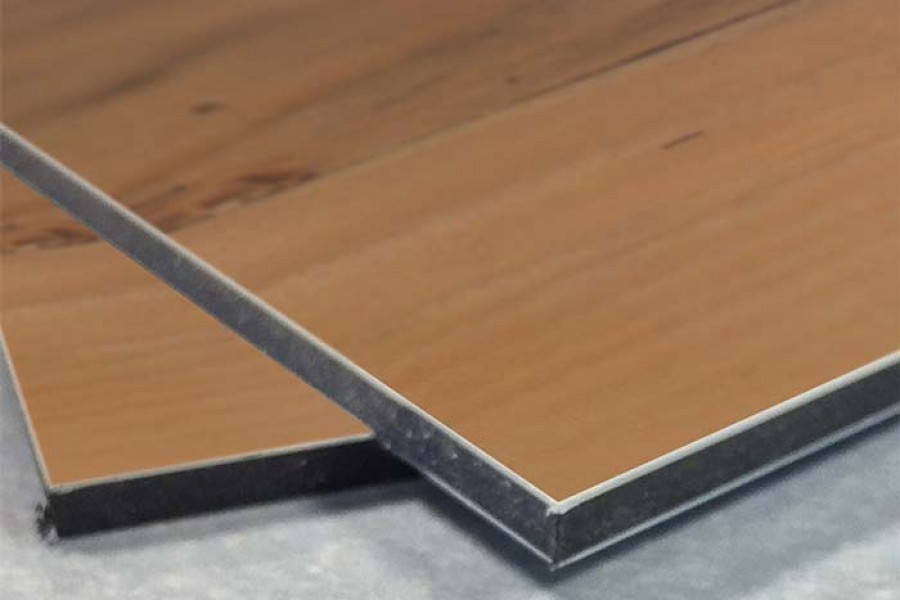

Our Dibond Signs are extremely durable. With rust, fade and weather resistance, these resilient aluminium composite sheets last for years. This signage is made from a polyethylene core sandwiched between two sheets of aluminium and is 3mm thick. Choose any size from 100 x 100mm to 1200 x 2400mm, printed single or double-sided, cut to shape and drilled to your specifications. Dibond printing is also available with a gloss or matt laminated finish to make your signage last even longer. Printed Dibond boards are recommended for shop and fascia signage, events and exhibitions. Ordering dibond printing is now even easier. Please request a quote if you need an option that is not available on this site, custom shape or holes drilled for example.- Please contact us for a size that is not listed on our website.

- UK shipping is free, exceptions apply.

- View our Artwork guide

Choose Printing Options

Material

Size

Lamination

Sides Printed

Double Sided

Turnaround Times

Quantity

More Prices

The price below is based on your chosen printing options above and relevent service.

Technical Specifications for Dibond Printing

- Scale of 1:1

- Include 3mm bleed on all sides

- Supply as a CMYK PDF

- Outline or embed fonts

- 150dpi resolution

- Available with drilled holes or cut to shape (upon quote request)

- Page 1 – artwork for print.

- Page 2 – artwork visual showing the cutting guide overlaid in 100% magenta.

- Page 3 – 100% magenta vector cutting guide. The cutting guide must consist of one solid keyline (no cut outs). We would also not advise using an overly complex cut line. (Shapes that are too complex may be rejected at prepress stage)

Order within

Delivery by

06-08-24